We offer custom sized enclosures for the electronics hobbyist or anyone in need of a sturdy aluminum chassis.

Our enclosures are made from 1/8" thick aluminum extrusion (patent pending) and 1/8" thick aluminum sheet.

These things are heavy and sturdy, not like most typical thin-walled boxes that bend and twist as you're drilling and punching holes.

After all, not many of us have access to a machine shop or even a drill press. Our enclosures are easy to work by hand and are very forgiving of a little slip-up.

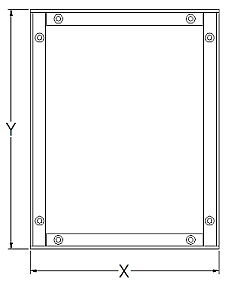

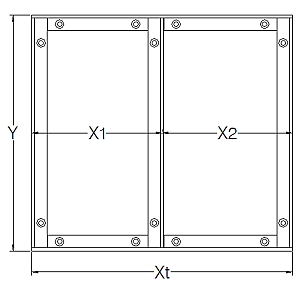

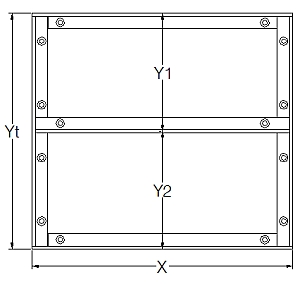

We currently offer 3 configurations that you can size to fit your specific application.

Note: The front and rear pieces overlap the side pieces. Also the front is the bottom of the images.

The Finishes

Unfinished (or Mill Finish)

This is how the material comes to us from the aluminum manufacturers.

It may have small marks from machine work and processing by us.

This requires full finishing work by you - sanding, painting, etc.

We apply a straight grained finish to the exterior of the enclosure using a rotating nylon fleece brush (similar to a Scotch-bright™ pad).

We do this by hand and it may add a day to manufacturing your order.

First we apply a brushed finish and then it is sent off for anodizing in the color of your choice.

Note that this is a non-conductive finish (WARNING!!! Anodized finish does not protect YOU against dangerous voltages). The anodized material can be scraped or sanded away to expose conductive aluminum.

Chromate Conversion Finish

Info

First we apply a brushed finish and then it is sent off for chromate conversion coating.

This finish is conductive. It also serves as a great base layer for paint, however it is not required.

Post-Customer-Machining Finish

This is a service we offer if you wish to have the finish done after you have performed your machine work.

We can perform any of the above services if you return your machined product(s) to us. Contact us for details.